Watch Rundongyang Parking Boxes video: explore diverse types, sleek appearance, usage, and quality tests to see our commitment to excellence.

At Rundongyang, we offer comprehensive packaging box solutions to meet diverse needs. With over 15 years of manufacturing expertise, we tailor services from design to product. Our wide array includes upscale premium, minimalist, and eco-friendly gift boxes, custom logo pill/medicine bottle boxes, and paperboard food gift boxes with inner lids.

Our packaging boxes offer full customization in shape, color, size, enabling custom/brand logo printing with adjustable sizes. We excel in matt lamination and embossing (including on corrugated board) for enhanced aesthetics. We use diverse materials like recycled/eco-friendly options, paperboard, and corrugated board. We ensure superior quality and structural integrity, offering fast delivery and OEM options. Our expertise provides flexible customization, boosting your brand's success.

Rundongyang offers comprehensive custom packaging box solutions for diverse industry needs. Our experience ensures high-quality products from standard to specialty types, guaranteeing perfect protection and brand presentation.

Cardboard Box: Versatile for light-to-medium products.

Corrugated Boxes: Strong, ideal for shipping heavy items.

Display Boxes: Enhances retail product visibility.

Mailing Boxes: Sturdy, for secure e-commerce/postal delivery.

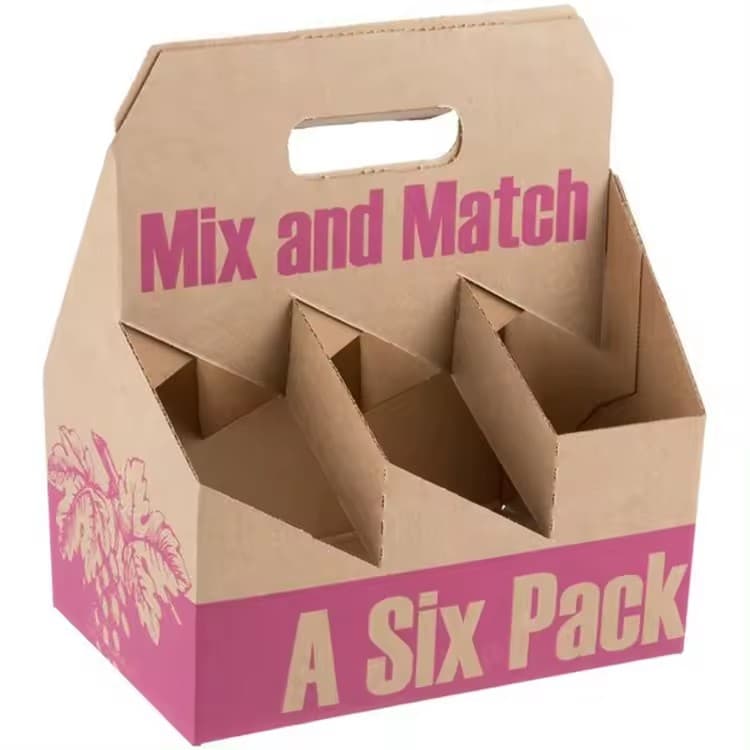

Gift Boxes: Includes luxury, minimalist, eco-friendly, food, wine/liquor custom options.

Medicine Boxes: Complies with standards for pharma/pill packaging.

Gifting and luxury product presentation

Pharmaceutical and medicine packaging

Food product packaging

Wine and liquor packaging

Retail display and brand enhancement

B2B partnerships

Shipping and mailing

At Rundongyang, we understand that packaging material selection is fundamental to product success and sustainability. We are committed to using high-quality, responsible materials to ensure our packaging boxes offer superior performance, aesthetics, and eco-friendliness. Our materials provide excellent protection and structural integrity, while also perfectly supporting various printing and finishing processes, helping your brand stand out. Through stringent supplier vetting and internal quality control, we guarantee every batch of material meets international standards, offering clients reliable customization choices.

Key Materials Include:

|

|

|

|

The creation of a packaging box involves a meticulous, multi-stage manufacturing process, ensuring precision and quality from concept to delivery. This step-by-step journey transforms raw materials into custom-designed, functional containers tailored to client specifications.

| Step | Description | Key Action / Purpose |

|---|---|---|

| 1. Design & Prototyping | Concept development, structural and graphic design, followed by physical sample creation for approval. | Finalize box structure and artwork; secure client sign-off. |

| 2. Material Selection | Choosing appropriate materials (e.g., paperboard, corrugated board, specialty boards) based on requirements. | Ensure optimal strength, aesthetics, and sustainability. |

| 3. Printing | Applying the approved design, branding, and text onto large sheets of the chosen material. | Transfer visual elements using offset or digital methods. |

| 4. Surface Finishing | Applying coatings (UV, aqueous), laminations (matte, gloss), or special effects (embossing, foil). | Enhance appearance, durability, and tactile properties. |

| 5. Die-Cutting | Cutting the printed and finished material into the precise, unfolded box shape using a custom die. | Create the exact contours of the packaging. |

| 6. Creasing/Scoring | Creating fold lines on the die-cut material. | Facilitate clean, accurate folding and easy assembly. |

| 7. Folding & Gluing | Assembling the flat, die-cut blanks into their final 3D box forms, often done automatically. | Construct the physical structure of the box. |

| 8. Quality Control | Ongoing inspection throughout all stages, checking print accuracy, cuts, adhesion, and overall integrity. | Guarantee adherence to quality standards and specifications. |

| 9. Packing & Shipping | Counting, bundling, and packing the finished boxes for safe and efficient delivery to the client. | Prepare products for dispatch and logistical handling. |

What did our happy clients say?

Our custom rigid gift boxes for beauty products are stunning! The 10x8x4" size with matte lamination and foil logo perfectly elevates our brand. Quality is impeccable. Rundongyang's professionalism is top-tier. Highly recommend for luxury packaging!

Rundongyang's medicine bottle packaging boxes were excellent for our new supplement line. The custom print and child-resistant features, sized for 30ml bottles, met all regulations. Professional service and durable quality. Strongly recommend for pharmaceutical packaging!

These paperboard food gift boxes for our chocolates are superb! The inner compartments secure each piece perfectly, and the eco-friendly material adds elegance (8x6x3"). Rundongyang's quality and service are truly professional. Highly recommend for food packaging!

We love Rundongyang's custom corrugated mailing boxes (12x10x6", kraft finish with logo)! They're incredibly sturdy for shipping our apparel and cost-effective. Their professional team ensured perfect results. Strongly recommend for any e-commerce business!