Product Details

| Place of Origin: | Heat Seal Bags Supplier |

|---|---|

| Brand Name: | Rundongyang |

| Certification: | FCC, CE, ISO |

| Model Number: | RDY- |

Payment & Shipping Terms

| Min Order: | 500 Pieces |

|---|---|

| Price: | $ |

| Packaging: | Standard cartons |

| Delivery Time: | 7-15 working days |

| Payment Terms: | TT |

| Supply Ability: | 10000 Piece/Pieces per Day |

Detailed Product Description

Heat Seal Packaging Bags are flexible, multi-layered pouches designed for the secure containment of various products.

| Item Name | Heat Seal Packaging Bags Manufacturer Aluminum Foil Custom Printed |

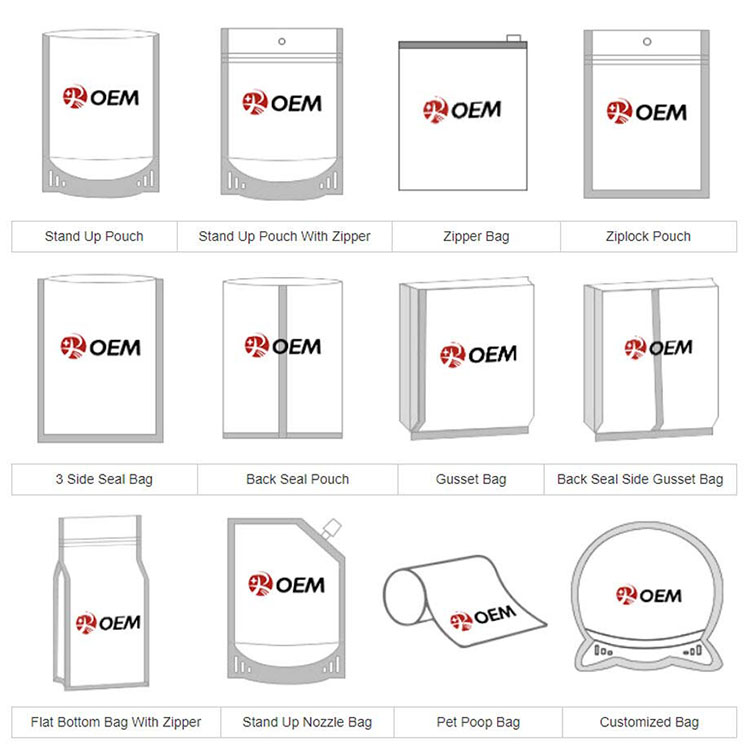

| Bag Style | Eight Sides Sealed Zipper Bag, Stand Up, Flat Bottom |

| Material | PET/PE, BOPP/CPP, Aluminum Foil, Kraft |

| Sealing Type | Heat Seal / Side Seal / Three-Side Seal |

| Thickness | 60–200 microns |

| Size | Customizable |

| Surface Finish | Matte / Gloss / Soft-Touch / Varnish |

| Printing | Gravure Printing (Max 10 colors) |

| Certification | FDA / SGS / ISO9001 |

| MOQ | 10,000 pcs |

| Features | ▶Excellent sealing performance to lock in freshness |

| ▶Compatible with automated packing machines | |

| ▶Custom logo and surface printing available | |

| ▶Moisture-proof, oxygen barrier, and light-blocking | |

| ▶Available with tear notch, hang hole, or zipper | |

| Applications | Snack food packaging; Frozen food or dry goods; Pet treats / Supplements; Non-food items (electronic parts, powders). |

| Advantages | 1) High Barrier Protection: Prevents air, moisture, UV penetration |

| 2) Custom Branding: Boosts retail presence with personalized print | |

| 3) Cost-Effective: Compatible with high-speed filling/sealing lines | |

| 4) Durable and Reliable: Leakproof, puncture-resistant material | |

| How to use | Fill the product inside manually or by machine Align the open end into the heat sealer Seal at the recommended temperature and time Store or distribute once sealed |

As a leading Heat Seal Packaging Bags Manufacturer, Rundongyang provides an expert solution that combines durability, high-barrier protection, and aesthetic customization.

A key feature is our use of high-quality materials, with a focus on Aluminum Foil. The aluminum foil laminate provides superior barrier protection, effectively preventing air, moisture, and UV light penetration to preserve product quality and extend shelf life.

Our pouches are designed to be compatible with automated packing machines, making them a cost-effective and efficient solution for high-speed production lines. With a customizable thickness of 60-200 microns, our bags are both durable and puncture-resistant, ensuring reliability during storage and distribution.

Aesthetic customization is another cornerstone of our offering. We use Gravure Printing to create high-quality, custom logos and designs in up to 10 colors. We also offer various surface finishes—Matte, Gloss, Soft-Touch, and Varnish—to enhance your brand's retail presence. For consumer convenience, our bags can be equipped with features like a tear notch, hang hole, or zipper.

High-Quality Materials: Certified FDA, SGS, and ISO9001 materials, including Aluminum Foil for superior barrier protection.

Excellent Sealing: Offers airtight, leakproof sealing via Heat Seal, Side Seal, or Three-Side Seal.

Advanced Barrier: Moisture-proof, oxygen barrier, and light-blocking to protect contents and extend shelf life.

Compatibility: Designed to work with automated packing machines for efficient production.

Customization: Custom printed with logos, available in various styles (Stand Up, Flat Bottom) and finishes (Matte, Gloss, etc.).

Durability: Puncture-resistant and reliable with a customizable thickness of 60-200 microns.

Consumer Convenience: Can be equipped with a tear notch, hang hole, or zipper.

High-Quality Printing: Gravure Printing up to 10 colors for vibrant branding.

Low MOQ: Starting at 10,000 pcs.

Snack Food Packaging: Ideal for chips, nuts, crackers, and other dry snacks.

Frozen Food or Dry Goods: Suitable for coffee, tea, spices, powders, and dehydrated foods.

Pet Treats / Supplements: Secure and high-barrier packaging for pet food and health products.

Non-food items: Perfect for electronic parts, chemical powders, seeds, or any product requiring high protection from external elements.

Bag Style: Choose from Eight Sides Sealed Zipper Bag, Stand Up, Flat Bottom, or other custom bag types.

Material: Select from Aluminum Foil, PET/PE, BOPP/CPP, and Kraft, or request a customized laminate.

Thickness: Customizable from 60 to 200 microns.

Size: Fully customizable to any dimensions.

Surface Finish: Available in Matte, Gloss, Soft-Touch, or Varnish.

Printing: Gravure Printing up to 10 colors for personalized logos.

Convenience Features: Custom additions of a tear notch, hang hole, or zipper.

24-hour Online Service: Rundongyang's commitment to customer satisfaction includes 24 hours online service, ensuring that you can receive timely support and answers to any questions you may have.

Problem Resolution: In the event of a product issue, our team is dedicated to providing efficient and effective solutions. We take full responsibility for any loss caused by our reasons, ensuring a smooth and reliable partnership.

As a leading Heat Seal Packaging Bags Manufacturer, we utilize advanced multi-layered laminates, with a key focus on Aluminum Foil. This material provides superior barrier protection, effectively preventing moisture, oxygen, and UV light penetration, which is critical for extending the shelf life of food, dry goods, and other sensitive items.

Our Heat Seal Packaging Bags are specifically designed for custom printed applications. We use professional Gravure Printing technology which can reproduce your logo and design in up to 10 colors. You can also choose from various surface finishes like Matte, Gloss, or a unique Soft-Touch to make your product stand out and enhance brand recognition.

Our standard MOQ is 10,000 pcs for custom orders to ensure cost-effectiveness for bulk production. The production time for custom Heat Seal Packaging Bags is typically 7-15 working days after the design is confirmed, allowing us to deliver your products efficiently.

Yes, our Heat Seal Packaging Bags are designed to be fully compatible with automated packing machines. Their precise dimensions and high-quality materials ensure a smooth workflow and a reliable seal on high-speed filling and sealing lines, which helps you reduce operational costs and improve production efficiency.

We offer a customizable thickness range from 60 to 200 microns. The thickness of our Heat Seal Packaging Bags directly impacts their durability and puncture resistance.

Yes, we provide comprehensive after-sales support. We offer 24-hour online service to address any questions or concerns you may have. Additionally, if any losses are caused by our reasons, we will take full responsibility, ensuring a reliable and trustworthy partnership for your Heat Seal Packaging Bags.